Portable Gas Detectors Vs. Fixed Gas Detectors

26/07/2021Gas monitoring and detection systems can save lives. They ensure workplace safety by alerting personnel to their exposure to toxic gas, the presence of combustible gases, and the lack of oxygen in a given area. Very broadly gas detectors fall into two broad categories, fixed or portable. Both types use a variety of sensor technologies to detect gas or vapour hazards. Both types have their own strengths and weaknesses and subcategories. In this article, we will give a brief overview of the application of fixed and portable gas detectors. The intention is to provide some background knowledge we feel is important when considering proposed solutions.

Fixed gas detectors are generally installed in large facilities and are used to both detect major leaks and as an early warning of gas leaking from a particular system. Fixed gas detection systems are configured using relays and customizable alarm point settings. These settings ensure that fixed gas detectors respond quickly to atmospheric hazards.

Typical applications for fixed detectors would be:

· Plant rooms/Boiler rooms

· Laboratories (school, university, commercial)

· Test Facilities

· Process Areas

· Gas Storage and bottling

Pros:

1. 24/7 continuous detection of the environment.

2. Provide you with automatic responses.

3. They can set to shut down a system once a leak reaches a specified alarm level.

Cons:

1. Capital installation cost can be expensive depending on the amount of equipment required

2. Due to their limited coverage ability, the likelihood of personnel and a leaking gas moving into the same uncovered area without warning from a fixed gas detector is extremely high.

3. They’re impractical for areas that may be cramped or difficult to reach.

4. Unlike portable detectors, fixed detectors require a main power supply.

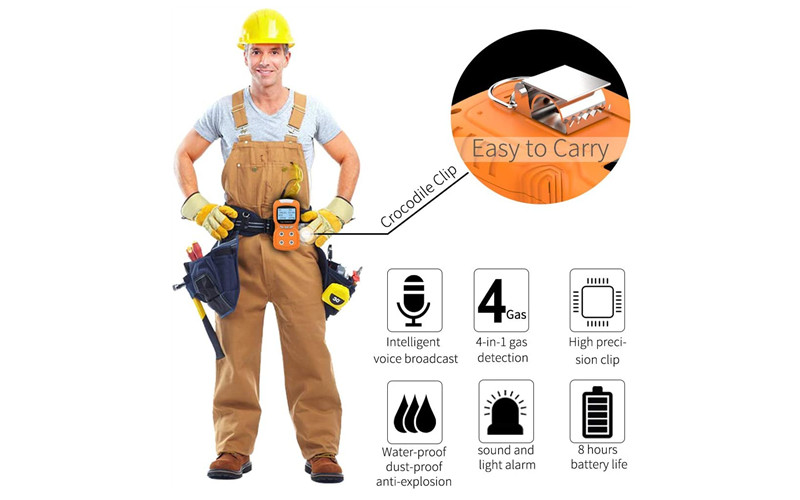

Portable gas detectors keep workers safe from atmospheric hazards by continuously monitoring the user’s breathing zone (which is typically within a 25cm radius of the user’s mouth.) Since these detectors must operate at close range to the user, they are often handheld, lightweight devices that can be easily worn or attached to a belt. For this reason, they are often referred to as personal gas detectors. Due to their size, they’re also often used to test confined spaces for safe entry.

Some application examples may be:

· Sewage workers

· Workers maintaining storage tanks (aircraft fuel tanks, process vessels, etc.)

· Gas delivery drivers

· Large process sites – generally in conjunction with a fixed system

Pros:

1. You can take this gas detector pretty much anywhere.

2. Portable gas detectors typically cost less than fixed gas detection systems.

3. Portable gas detectors are the safest measure for workers under the threat of either continuous exposure or unstable atmospheric conditions.

Cons:

1. Does not provide 24/7 monitoring

2. To ensure proper usage, operators must be carefully trained.

3. Portable gas detectors don’t provide automatic responses, leaving the user to take action on their own in the event of a gas leak.

Deciding Between Fixed and Portable Gas Detectors

The following factors will determine which gas leak detection equipment is most appropriate for you:

——The source of the gases

——Whether the hazard is temporary or chronic

——Environment of the site

——Typical occupancy of the affected site

——Time required for workers to safely exit the affected area

——Training required to operate the detection system

——Expense

The above examples are deliberately reductive and are posed to offer a very basic idea of the differing applicability between fixed and portable gas detectors. There are, of course, myriad additional things to consider before selecting a gas sensing solution. Therefore, you should always consult the manufacturer or trained/certified distributor agent when it comes to selecting which equipment you require for your site.